Design & development

Innovation and boldness from the start.

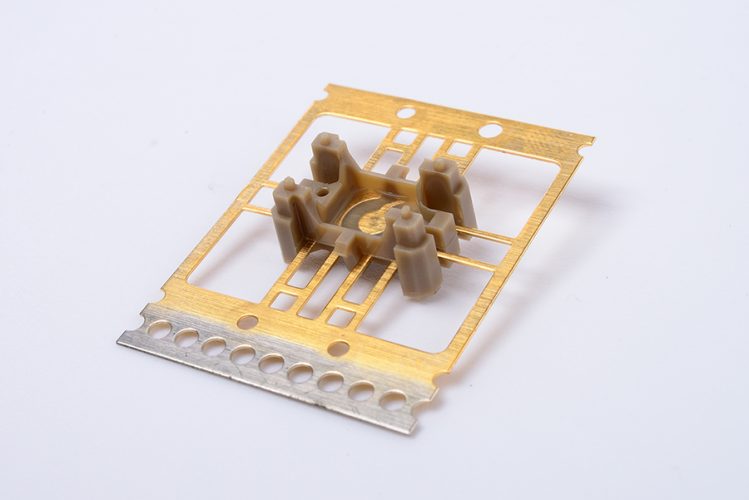

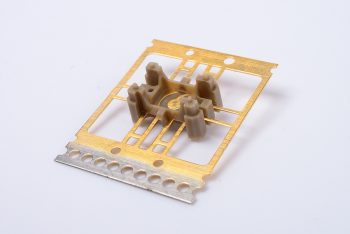

We work in direct collaboration with our clients from the conception of their projects. The interface between the clients’ needs and our specific expertise, at all stages of the fabrication process, allows us to construct innovative solutions, optimising tools, industrialisation and efficient mass production.

Our added value

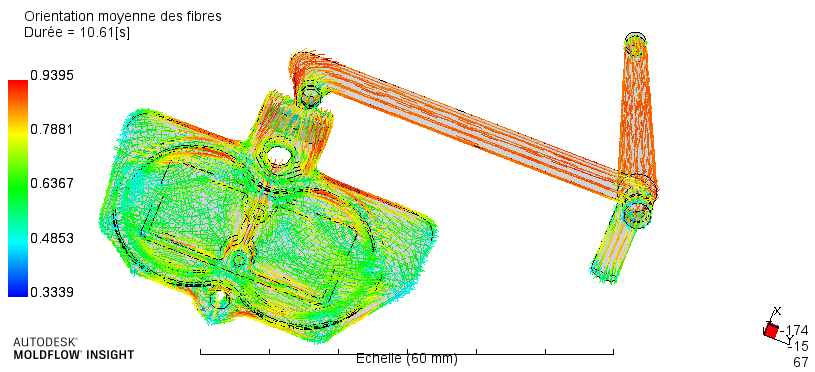

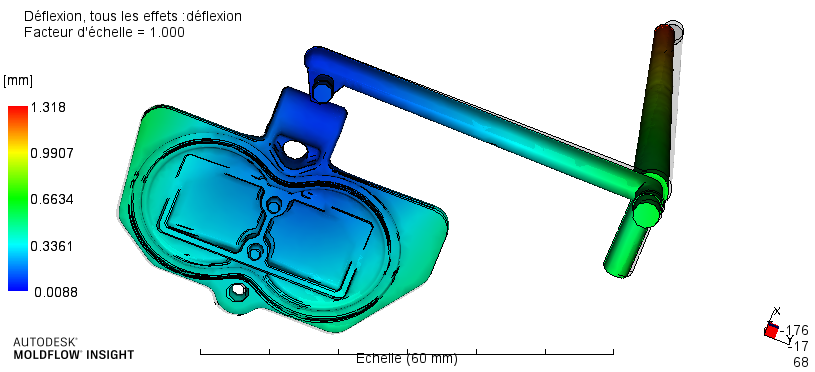

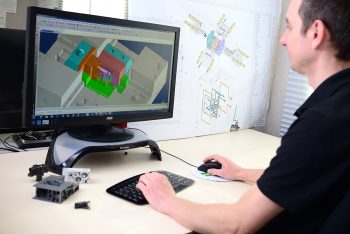

Integration of Moldflow® rheology software.

We use Moldflow® software, a computer-aided engineering (CAE) simulation package, to anticipate material behaviour during plastic injection moulding. An innovative tool that makes production more reliable, optimises efficiency and reduces costs.

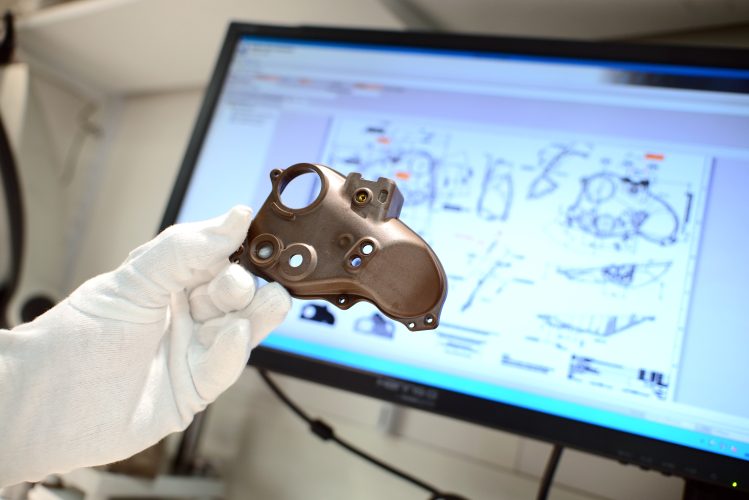

Specialised expertise.

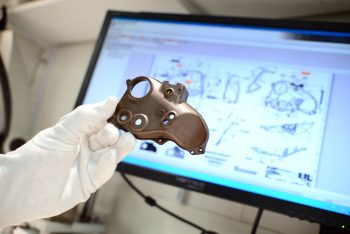

With mastery over 400 different thermoplastic materials: we are well situated to guide our clients which ones make the difference, which is the most efficient and the most durable. Our constant monitoring, allows us to stay one step ahead and to offer new, bio-sourced, recycled, materials which are mechanically more resistant and technically innovative.

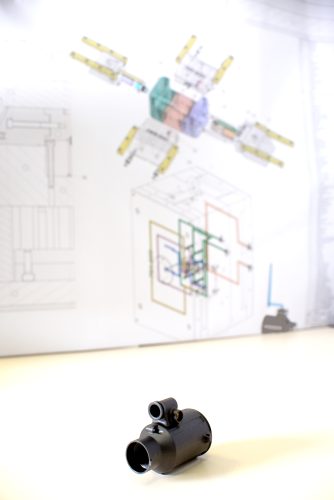

An experienced design team.

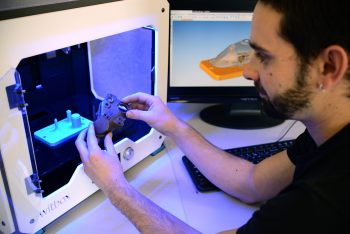

Accustomed to meeting the most ambitious challenges, we develop high quality solutions, that meet the challenges of our customers. To do this, we use cutting-edge technology: 3D printing, latest generation software, rheology, etc…